Control Panel Instruments

Control Panel Instruments

SCADA, an acronym for Supervisory Control and Data Acquisition, is a critical component of industrial automation and control systems. It plays a pivotal role in monitoring, controlling, and managing various processes within industries such as manufacturing, energy, water treatment, and more. The primary objective of a SCADA system is to collect real-time data from sensors and devices in the field, transmit it to a central control location, and enable operators to make informed decisions to optimize processes and ensure efficiency.

By customizing the SCADA system for Equitel’s unique needs, the organization can achieve a comprehensive and integrated approach to monitoring and controlling both industrial and financial processes, ensuring operational excellence and regulatory compliance.

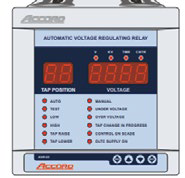

Automatic Voltage Regulator

A microcontroller based architecture used to regulate the secondary voltage of power transformer and distribution transformer with ON-LOAD tap changer (OLTC). This system electrically Isolated from Input power supply. SCADA Compatible model with inbuilt Tap Position Indicator.

Digital Frequency Meter

A microcontroller based frequency meter is used to measure the grid/line frequency.

Digital Ammeter/ Voltmeter

Microcontroller based 3 phase/1 phase digital ammeter and voltmeter for measuring the current/ voltage of the phase through CT/PT. User selectable display range/ PT & CT Primary. Compatible with SCADA and data logging features

Digital Multi-Function Meter

Microcontroller based system used to measure various electrical parameters like V, I, power factor , Hz, KVA, KVAR, KW & KWH. Compatible with SCADA and DATA Logging features.

MW, MVAR. PF Meter

Microcontroller based module designing with CAD Circuit technology , Stable indication even in case of wide power supply fluctuations (for self-powered & Aux. Powered transducers). With SCADA compatible module available with RS485 communication protocol.

Annunciator of 4W/6W/8W/10 W/12 W/ 16W/18W/20 W

This scheme is highly efficient, accurate and intelligent Microprocessor Based machine called Alarm Annunciator which continuously scans the fault conditions.